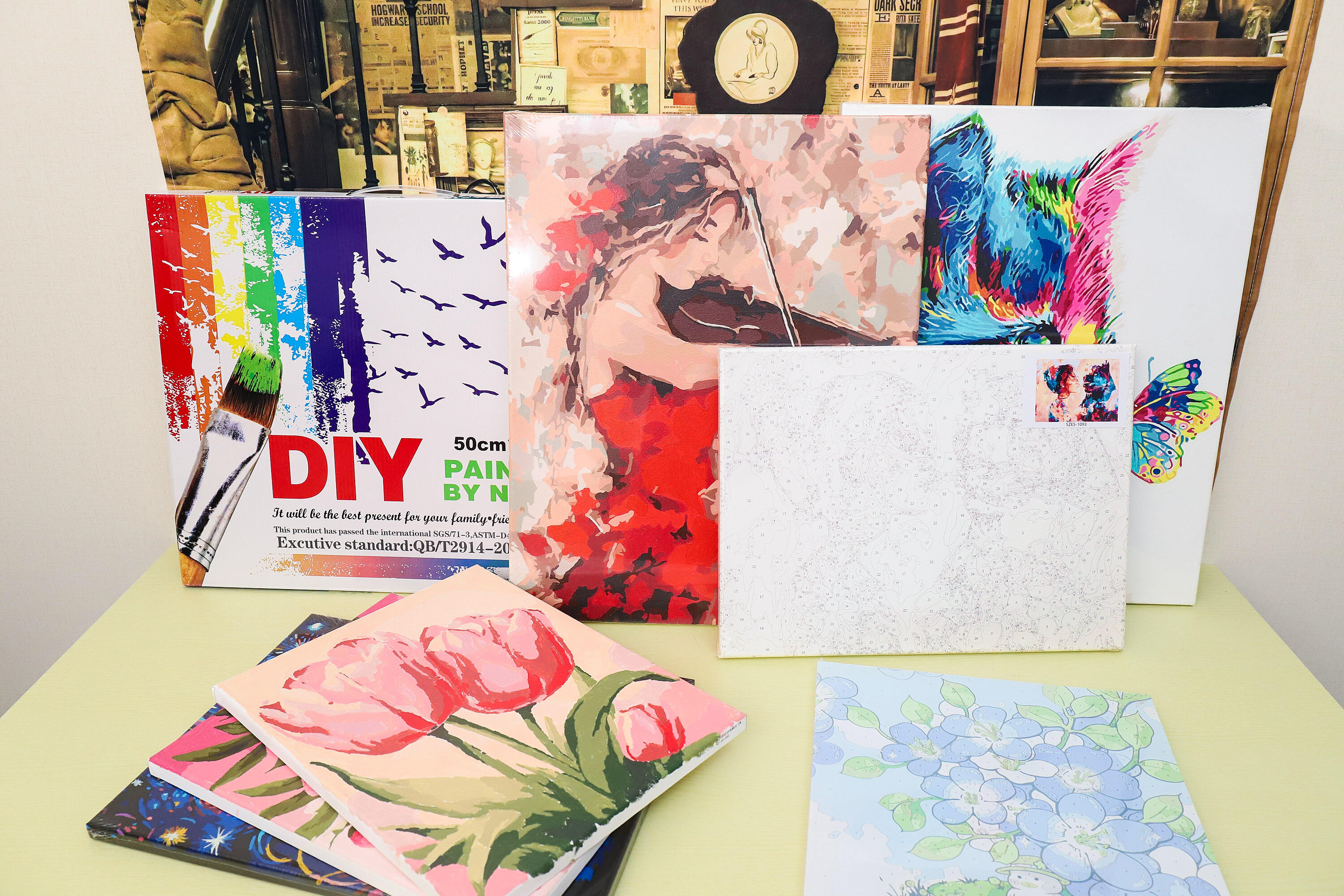

Premium Material Standards for Durable and Accurate Canvases

Canvas Material Quality: Cotton, Polyester, Linen, and Alternatives

The best paint by number manufacturers focus on quality materials that last, and according to the Art Materials Safety Report from 2022, around 72% of top tier kits actually come with triple primed cotton or linen canvases. Cotton works really well for absorbing paint and stands up better when it gets tugged on, whereas linen holds its shape much better over time, showing about 40 percent less warping compared to those polyester mixtures. When companies need to keep costs down, they tend to go for cotton polyester blends, but the real serious ones stick with odor free flax linen for pieces meant to be framed eventually.

Print Accuracy and Clarity of Numbered Patterns on Canvas

Industrial-grade inkjet printers with 1200+ dpi resolution ensure numbered outlines remain visible under acrylic layers. Factories achieving <0.1mm registration error use spectrophotometers to verify contrast ratios between ink and canvas—a critical step often skipped in budget kits, where 23% of users report obscured numbering (2023 Hobbycraft Survey).

Stretcher Bar Construction, Thickness, and Professional Stretching Techniques

Kiln-dried pine stretcher bars (minimum 1.5" thickness) resist warping across humidity changes. Premium workshops employ gallery-wrapping techniques with four or more cross-bracing points, avoiding the single-layer stapling found in mass-market kits that contributes to 68% of consumer-reported canvas sagging (DIY Art Trends 2024).

Long-Term Durability and Preservation of Finished Paint by Number Artwork

UV-resistant acrylic primers and pH-neutral canvases prevent yellowing, with leading factories guaranteeing 50+ year color fastness under proper display conditions. In contrast, low-cost alternatives show pigment degradation within 2–3 years under standard indoor lighting.

High-Performance Acrylic Paints with Consistent Color and Coverage

Acrylic Paint Quality: Opacity, Fluidity, Safety, and Low Odor

Reputable factories use acrylics compliant with ASTM D-4236 safety standards, ensuring non-toxic formulas suitable for extended use. Premium paints achieve 92% opacity (Art Materials Safety Report 2023) through concentrated pigments, enabling single-coat coverage with smooth application. Low-odor formulations keep VOCs below 50 g/L, making them ideal for indoor environments.

Managing Paint Consistency and Preventing Premature Drying in Kits

Retarders are added to acrylic bases to extend working time by 40% compared to standard craft paints. Pre-sealed pots with silicone liners maintain ideal viscosity for 12–18 months when unopened, reducing drying risks during shipping and storage.

Color Accuracy and Minimizing Deviations Between Provided Paints and Canvas

Advanced color-matching systems align canvas printing with paint batches using Pantone-validated processes. Digital proofing reduces shade mismatches to <1.5 ΔE (CIEDE2000 industry standard), as outlined in professional paint-by-number guides.

| Pigment Type | Cost per Liter | Lightfastness | Color Intensity |

|---|---|---|---|

| Synthetic Organic | $28 | 8/10 | 9/10 |

| Natural Mineral | $51 | 9/10 | 7/10 |

Synthetic vs. Natural Pigments: Performance and Cost Trade-Offs

Natural earth pigments offer excellent UV resistance, but synthetic alternatives dominate production due to 45% lower costs and consistent batch reproducibility. Hybrid systems blend synthetic bases with mineral stabilizers to balance durability and affordability.

Impact of High-Quality Paints on Final Artwork Appearance and Customer Satisfaction

Kits featuring professional-grade acrylics report 89% customer satisfaction (Craft Materials Survey 2024), with 72% of users achieving gallery-worthy results. Consistent texture and color fidelity reduce beginner frustration while meeting advanced painters’ expectations for detail.

Precision in Numbering, Printing, and Color Matching Processes

Ensuring Numbering Accuracy Across Complex Paint by Number Designs

Top factories employ automated error-checking systems, achieving 99.6% numbering accuracy in intricate designs according to a 2023 print quality audit. Multi-stage validation protocols cross-reference digital files with physical proofs to eliminate issues like overlapping labels or misaligned grids in detailed landscapes and portraits.

Digital Proofing and Quality Checks to Eliminate Labeling Errors

Digital proofing workflows using industry-standard software reduce labeling errors by 82% compared to manual checks. High-resolution pre-print simulations allow detection of inconsistencies at 400% magnification before production, ensuring crisp 0.3mm numbering that remains legible after painting.

Color Management: Matching Printed Canvas Tones With Actual Paint Shades

Spectrophotometers are used to maintain ΔE ≤2 color tolerances between printed canvases and acrylic paints. This precision prevents the 37% customer dissatisfaction rate reported in 2023 studies due to noticeable hue deviations. Real-time ink adjustment systems ensure batch consistency across thousands of kits, compensating for absorption differences in various canvas types.

Calibration and Pantone Matching in Large-Scale Paint by Number Factory Printing

Regular Pantone certified calibration checks keep color variations below 1.5 NBS units during large scale manufacturing runs. Modern industrial inkjet systems come equipped with automatic viscosity control features that help maintain just the right pigment concentration levels. This is really important when trying to get those lifelike skin tones right in portrait prints or capture those gentle transitions between colors in landscape images. With these quality control measures in place, most factories can successfully reproduce around 98 out of every 100 colors from customer submitted artwork files, staying well within acceptable visual differences according to industry standards.

Functional Brush Design and Kit Usability for All Skill Levels

Standard Brush Types and Their Suitability for Detailed vs. Broad Strokes

Premium kits include brushes optimized for different techniques: round-tip brushes (3–5 mm) handle fine details and numbering, while flat brushes (8–12 mm) efficiently cover large areas. Tapered synthetic bristles reduce streaking in acrylics by 40% compared to uneven natural fibers, according to the 2023 Brush Functionality Report.

Brush Durability, Maintenance, and User Experience in Entry-Level Kits

Bristle shedding is the top complaint in budget kits. Leading manufacturers now use triple-ferrule brushes with knot-free nylon bristles, which shed 92% less over 50+ uses. Including cleaning cards and usage guides helps beginners manage paint consistency and prolong brush life.

Enhancing Usability Through Thoughtful Tool Selection in Paint by Number Kits

Forward-thinking factories incorporate ergonomic handles (10–12 cm length) for comfort during long sessions and color-code brushes to match canvas zones. A 2024 consumer survey found that kits with dedicated detail brushes and angled shaders improved completion rates by 63% across age groups, enhancing accessibility without sacrificing artistic quality.

Customer-Centric Manufacturing and Brand Trust in the Paint by Number Industry

Leading paint by number factories emphasize transparent product representation to align marketing visuals with actual deliverables. A 2023 Consumer Insights Study revealed that 78% of customers value realistic previews of canvas details and paint shades when evaluating trustworthiness, as exaggerated enhancements often lead to disappointment.

After-Sales Support, Language Accessibility, and Responsiveness

Factories with 24/7 multilingual support reduce customer frustration by 62% compared to brands offering only email assistance. Proactive solutions—such as replacing dried paint pods or misprinted canvases—minimize disruptions, with 89% of users more likely to repurchase from brands providing no-questions resupply options.

Balancing Mass Production With Consistent Quality in Paint by Number Factory Output

Quality control happens at three main points pigment mixing, canvas printing, and putting together the kits which keeps things consistent when scaling production up. Factories that have implemented these automated color matching systems see about 40 percent fewer problems with colors not matching compared to places still using old school Pantone charts manually. When manufacturers actually listen to what customers want accurate representations of products online and quick fixes for any defects they find this builds trust. The result? First time buyers become real fans of the brand. According to the Arts & Crafts Loyalty Report from 2023, around 72% of happy customers end up telling others about their favorite supplier within just six months.

FAQs

What materials are best for canvases in paint by number kits?

The best materials for canvases are triple primed cotton or linen, as they absorb paint well and hold their shape over time, showing less warping.

How do high-quality paints affect the final appearance of paint by number artwork?

High-quality paints lead to improved texture and color fidelity, reducing beginner frustration and meeting advanced painters' expectations, resulting in a gallery-worthy finish.

What support is available if there are defects in a paint by number kit?

Reputable manufacturers offer 24/7 multilingual support and proactive solutions, such as replacing dried paint pods or misprinted canvases, to minimize disruptions.

Table of Contents

- Premium Material Standards for Durable and Accurate Canvases

-

High-Performance Acrylic Paints with Consistent Color and Coverage

- Acrylic Paint Quality: Opacity, Fluidity, Safety, and Low Odor

- Managing Paint Consistency and Preventing Premature Drying in Kits

- Color Accuracy and Minimizing Deviations Between Provided Paints and Canvas

- Synthetic vs. Natural Pigments: Performance and Cost Trade-Offs

- Impact of High-Quality Paints on Final Artwork Appearance and Customer Satisfaction

- Precision in Numbering, Printing, and Color Matching Processes

- Functional Brush Design and Kit Usability for All Skill Levels

- Customer-Centric Manufacturing and Brand Trust in the Paint by Number Industry

- FAQs